Our in-depth knowledge of special processes is critical for all the complex devices we design and assemble. Our skills encompass several high-level professions: welding, soldering, sheet-metal working, spatial bonding, crimping, bending, forming, hot metal spraying or even refractory metalworking.

Micro welding and orbital welding MIG / TIG

Description :

- Stainless steel, Aluminium

- Controlled environment

- According to NFEN ISO 15614

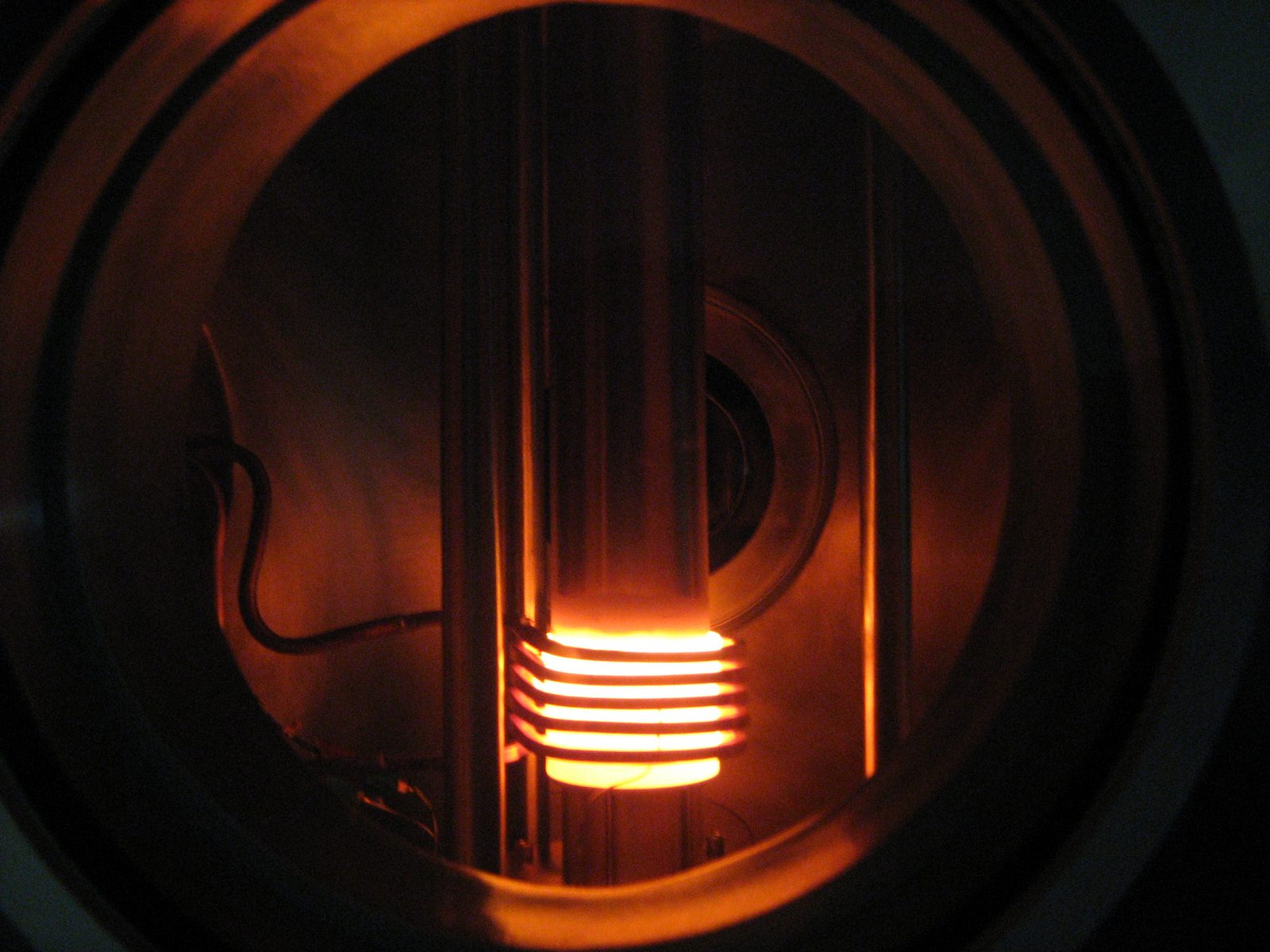

High temperature brazing

Description :

- Vacuum chamber with induction heating

- Useful capacity: 400x400mm

- High temperature: 1100°C

- Stainless steel, tantalum – Nickel Chrome Brazing

- According to RCCMX code

Silver / Tin Brazing alloy

Description :

- Oxyacetylenic

- Ag brazing according to RCCM

- Wire soldering according to IPCA610, IPC A-620

Spatial bonding and compounding

Description :

- gluing, filling, encapsulation, etc.

References : EC2216, Ecobond 144, …

Hot metal or refractory layers spraying

Description :

- Protection against abrasion, corrosion – insulation/thermal barrier

- Metals: Copper, Aluminium, Molybdenum, Stainless Steel, Nickel Chrome.

- Refractory material: Alumina, Calcium Zirconate.

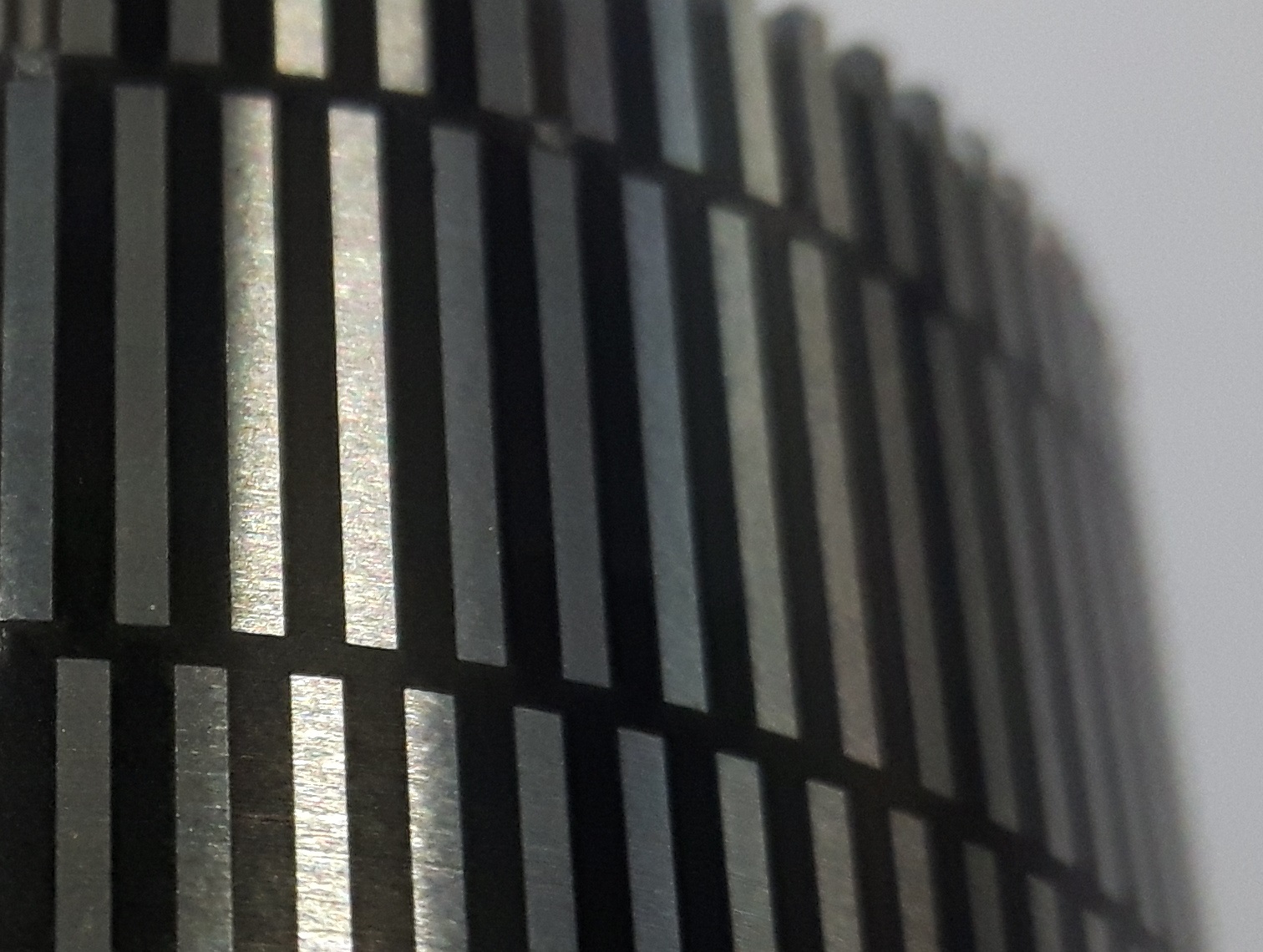

Sheet metal working

Description :

- Aeronautics qualified workshop for medium and large series (unique parts to several thousands).

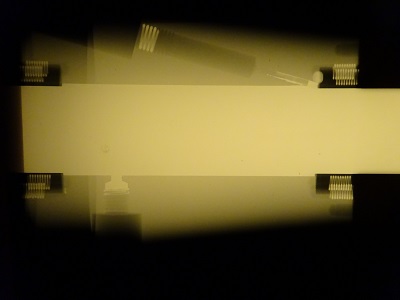

Non-destructive testing

Description :

- SOTEREM operate different non-destructive testing technologies usefull for your projects, from X-ray to red organol inspection