Our assemblies

SOTEREM designs and manufactures complex instrumented assemblies by the use of high value-added processes:

- welding of highly integrated assemblies

- soldering of watertight passages

- instrumentation forming (thermocouples, heating elements, collectors,…).

SOTEREM started in 1975 with the integration of irradiation devices for the CEA and produces that kind of devices ever since.

Irradiation furnace

Description :

Tubular furnace for temperature modulation of devices to be irradiated.

References : CHOUCA, CALIPSO

Technical specifications :

- temperature control from 250°C to 400°C

- double tubular casing

- Thermocouples for temperature control

- fine instrumentation management

- metallic hot spraying (projection) on heating elements to improve conductivity

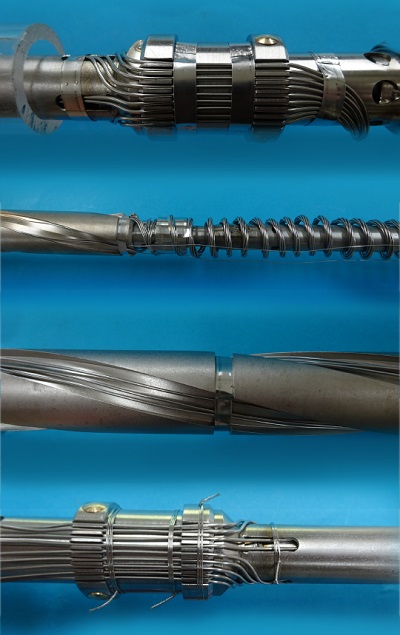

Irradiation devices

Description :

Devices involved in the core of experimental reactors

References : specimen holders, refrigeration tubes,…

Technical specifications :

- mechanically welded slender assembly (up to 6m long)

- 1mm to 300mm diameter

- stainless steel, aluminium, zircaloy, inconel…

- instrumentation forming

- Hermetic feedthrough (helium leak tested)

- Codes : ESP, ESPN

- Standards :RCCM, RCC-MX, RCC-MRx

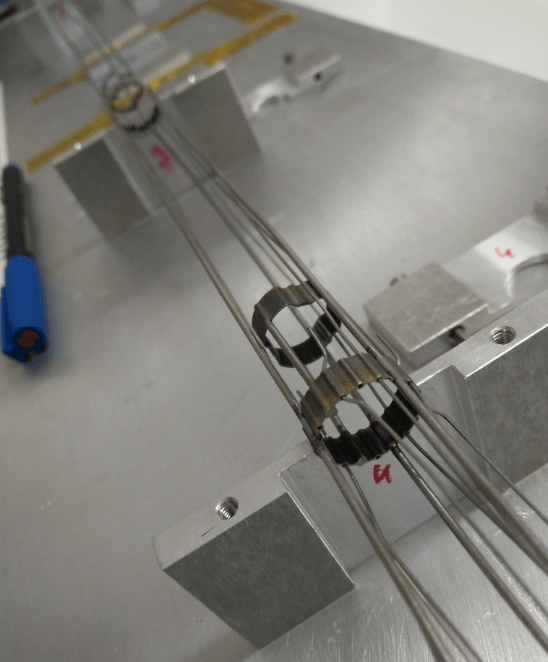

Instrumented experimental devices

Description :

Mechanically welded or mechanically screwed instrumented assemblies

Références : for research organizations, laboratories

Characteristics :

- customer-specific design

- thermocouples, heating elements, heaters, pressure measurements, etc.

- implementation and development of special processes when required